You've seen it a thousand times: those incredible, ground-hugging clouds of fog that roll across a stage at a concert or during a dramatic theatre scene. This isn't your standard party fogger filling the room with haze. This is the work of a specialised low fog machine, a piece of kit designed specifically to create a dense, low-lying effect that adds a whole new level of atmosphere.

These machines use a clever cooling process that makes the fog heavier than the air around it, forcing it to stay close to the floor for that unforgettable, dramatic look.

How Low Fog Machines Create Unforgettable Atmospheres

So, how do live productions conjure those stunning, ankle-deep clouds that seem to have a life of their own? It might look like magic, but the secret is all down to some basic physics. For AV professionals and venue managers, low-lying fog is a game-changing tool. It creates a sense of drama and immersion that you just can't get with standard fog, turning a product reveal into a monumental event or a theatrical entrance into something truly mysterious.

The Science of Staying Low

Think about opening your freezer door. That little wisp of cold air that spills out and sinks to the floor? Low fog machines work on that exact same principle: cold air is denser than warm air.

By rapidly chilling the fog just as it's produced, the machine makes it dense enough to resist its natural urge to rise and mix with the warmer air in the room. This is what keeps that beautiful, thick blanket of fog right where you want it—on the ground.

The whole process relies on a few key components working together perfectly:

- A Standard Fogger: It all starts with a heating element that vaporises a special water-based fluid, creating a normal cloud of fog.

- A Cooling Mechanism: This is the crucial step. The hot fog is immediately pushed through a powerful chilling system.

- Dense Output: Once cooled, the fog is now much heavier. It tumbles out of the machine and spreads across the floor instead of floating up into the air.

The core principle is straightforward: cool the fog to make it heavier than the ambient air. This simple scientific concept is responsible for creating one of the most visually impressive effects in live production.

Essential Components for the Perfect Effect

To get that rapid cooling, low fog machines typically use one of two technologies. The first, more traditional method uses a chamber packed with either regular ice or dry ice to chill the fog as it passes through. The second, more advanced approach involves cryogenic systems that use liquid CO₂ or even built-in refrigeration units for incredibly precise and powerful cooling.

It's not just about the machine, though; the fluid is just as important. These systems require specialised quick-dissipating fluids. This type of fluid is formulated to evaporate as it warms back up to room temperature, which is essential for stopping the venue from filling up with a lingering haze that would completely ruin that clean, ground-level look. Getting your head around this foundational science is the first step to choosing the right tech for your venue.

Exploring Different Types of Low Fog Machines

To get that iconic, floor-hugging fog, every machine needs a way to cool the smoke down. While the final effect might look similar from one machine to another, the technology under the bonnet is often quite different, and each comes with its own set of demands and advantages.

Getting your head around these differences is the first real step in matching the right bit of kit to your venue. You'll generally come across two main camps: ice-based chillers and the more advanced cryogenic systems. One is simple and cheaper to buy, while the other offers the kind of rock-solid control needed for professional shows.

Ice-Based and Dry Ice Machines

The most direct way to create low fog is to simply chill it with ice. Machines that do this, often called fog chillers, are basically just insulated boxes you fill with regular ice cubes or, for a more intense effect, dry ice (which is solid carbon dioxide). A standard fogger then just pumps its hot, vaporised fluid through this freezing cold chamber.

As the hot fog hits the cold surface, its temperature drops like a stone. This makes it much denser than the surrounding air, causing it to sink and creep across the floor when it comes out. It’s a popular method because it’s straightforward and the initial cost is low, which is great for smaller venues or anyone working with a tight budget.

But that simplicity does have its downsides:

- A Bit of a Chore: You have to physically load them with ice, which then melts and needs draining. It can get wet and messy.

- Inconsistent Results: As your ice inevitably melts during a show, its cooling power fades, and your fog effect can start to thin out or rise.

- Ongoing Costs: The machine itself might be a bargain, but the cost and hassle of getting hold of huge amounts of dry ice for every single performance can really start to add up.

Cryogenic and Refrigerated Machines

When you get to high-end touring, broadcast studios, or big theatre productions, cryogenic and refrigerated systems are the only way to go. Instead of ice, these professional low fog machines use some seriously clever cooling tech to give you precise, powerful results every time.

Cryogenic models are plumbed into a tank of liquid CO₂. They inject this directly into the fog stream, flash-freezing it to an incredibly low temperature. Refrigerated units are a bit more self-contained, working just like a freezer with a compressor and cooling coils to chill the fog.

The payoff is a stunningly dense, consistent, and controllable low-lying fog that can run for ages without anyone needing to touch it. You can see this level of technology in action in advanced gear like the new fog blaster range from Mac Mah now available through specialist suppliers.

Sure, the initial investment is a lot higher, but cryogenic and refrigerated machines deliver the kind of reliability and precision that professional shows absolutely depend on. They're cleaner, create less mess, and slot perfectly into complex, DMX-controlled lighting and effects setups.

This is exactly why they're the first choice for any job where things just have to work perfectly, every single time.

Comparing Low Fog Machine Technologies

To make the choice clearer, let's break down the key differences between these two approaches. The right machine for you really depends on balancing your budget against your need for consistency and control.

| Feature | Ice-Based and Dry Ice Machines | Cryogenic and Refrigerated Machines |

|---|---|---|

| Cooling Method | Uses regular ice or solid CO₂ (dry ice) that must be manually loaded. | Uses liquid CO₂ from a tank or a built-in refrigeration compressor. |

| Upfront Cost | Lower. More accessible for smaller budgets and occasional use. | Higher. A significant investment for professional-grade equipment. |

| Running Costs | Can be high due to the constant need to purchase and transport ice. | Generally lower, as consumables (like CO₂) are used more efficiently. |

| Operation | Labour-intensive. Requires setup, loading, and messy cleanup/draining. | Automated. Set it up and it runs on its own, often with DMX control. |

| Consistency | Variable. The fog effect can weaken as the ice melts over time. | Extremely consistent. Delivers the same high-quality effect for hours. |

| Best For | Mobile DJs, small clubs, theatrical productions with limited budgets. | Large-scale concerts, TV/film production, permanent installations. |

Ultimately, ice-based machines are a fantastic entry point, but for any serious commercial or touring application where the effect is critical, investing in a cryogenic or refrigerated system pays for itself in reliability and peace of mind.

Decoding Key Technical Specifications

For any AV integrator, the spec sheet is the roadmap. When you're looking at professional low fog machines, those numbers tell the real story of how a unit will perform on the ground. Getting your head around these metrics is the difference between an effect that elevates a show and one that just… falls flat.

These specifications aren't just about power ratings. They reveal a machine’s capability, its efficiency, and crucially, how well it will play with the rest of your complex production setup. Let's break down what these key numbers actually mean for your projects.

Output Volume and Coverage

First up is Output Volume, usually measured in cubic feet per minute (CFM) or cubic metres per minute (CMM). You can think of this as the machine's lung capacity – it tells you how fast and how effectively it can fill a given space. A machine with a 4,000 CFM rating, for example, can saturate a 4,000 cubic foot area in a single minute.

For a small theatre stage, a lower CFM might be all you need to create a subtle, atmospheric layer. But if you’re working in a large concert arena or a cavernous ballroom, you’ll need a much beefier output to get that dense, uniform blanket of fog before it starts to rise and dissipate.

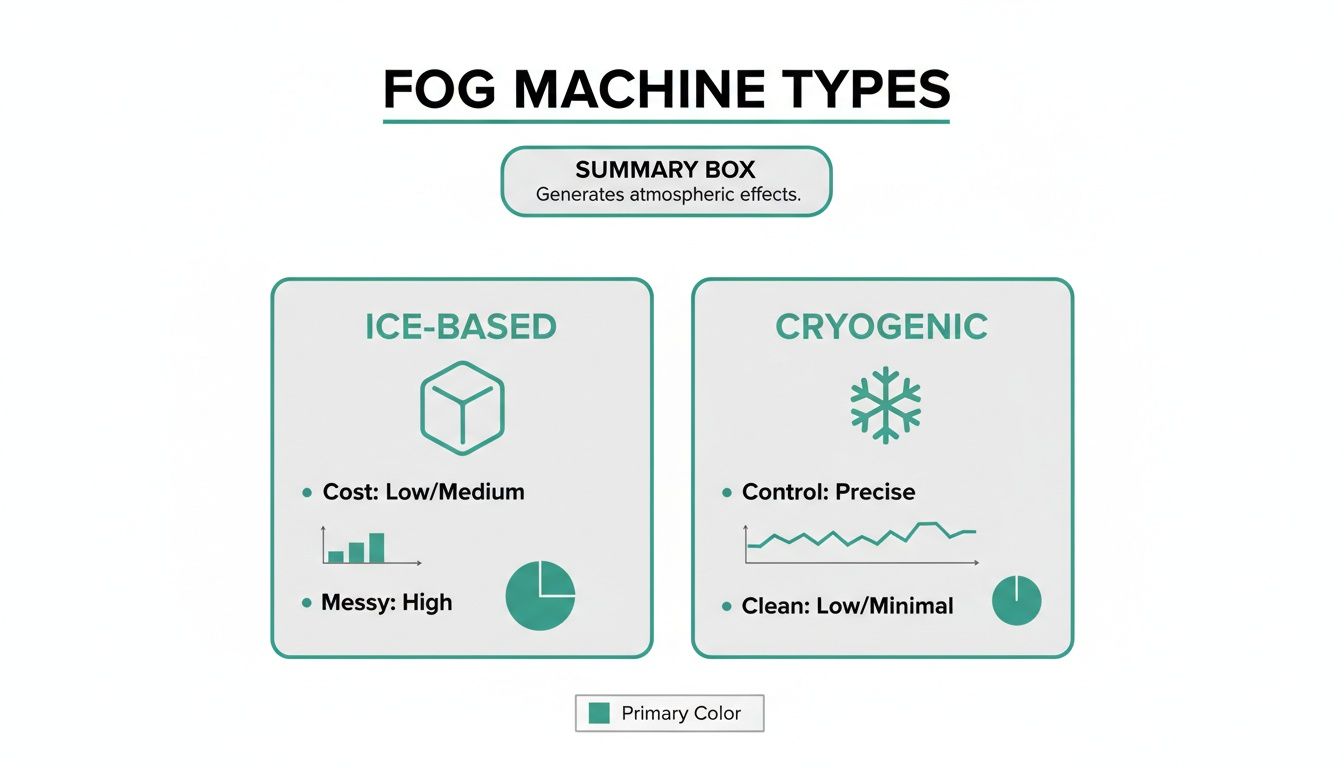

This infographic gives a simple visual breakdown of the two main types of low foggers we’ve discussed.

It really highlights the trade-off you make: the affordability and straightforward nature of ice-based units versus the clean, precise control you get from professional cryogenic systems.

Heat-Up Time and Fluid Consumption

In the world of live events, timing is non-negotiable. A machine's Heat-Up Time is how long it takes to get show-ready from a cold start, which typically ranges from 3 to 10 minutes. A shorter heat-up time is a lifesaver on jobs with tight setup windows or when you need quick turnarounds between acts.

Just as important is the Fluid Consumption Rate. This number dictates how long a full tank of fluid will last, directly impacting your running costs and the logistics of a show. A machine that sips fluid is not only more economical but also means less hands-on faffing during an event. The last thing anyone wants is a disruptive mid-show refill. As the UK fogging machine market has grown, manufacturers have focused heavily on developing more efficient technologies. You can find more insights on the UK market from Research and Markets.

DMX Control Integration

For any serious production, DMX (Digital Multiplex) control is an absolute must-have. DMX is the industry-standard language that lets a lighting console talk to and control all sorts of stage effects, including your low fogger. It’s what turns the machine from a simple on/off box into a fully integrated part of a synchronised show.

DMX control is what allows you to "play" the fog machine like an instrument. You can cue precise bursts of fog to match a musical beat, slowly fade the effect in for a dramatic entrance, or adjust fan speed to direct the flow on stage.

A typical low fog machine might use between 1 to 3 DMX channels to give you granular control over different parameters:

- Channel 1: Fog Volume/Output (This controls the intensity of the fog burst)

- Channel 2: Fan Speed (This adjusts how forcefully the fog is pushed out)

- Channel 3: Interval/Duration (Lets you set automated timing for repeated fog bursts)

Once you understand these specs, you can look at any machine and know instantly if it has the power, efficiency, and control your productions demand.

Integrating Low Fog Machines with Venue HVAC Systems

You can have the best low fog machine on the market, but its breathtaking effect can be utterly ruined by an invisible enemy: the venue’s HVAC system. Even the slightest whisper of air from a heating, ventilation, or air conditioning unit can disrupt the delicate temperature balance that keeps the fog hugging the floor. The result? The fog lifts, swirls, and turns into a messy, unwanted haze.

Getting this right isn’t just about the machine; it’s about mastering the environment. This means getting proactive and building a relationship with the venue’s facilities team to control the single biggest variable in the equation. Think of the fog as a shallow pool of perfectly still, cold water—any ripple will disturb the entire surface.

Conducting a Pre-Show Site Survey

Before you even think about where to place a machine, a thorough site survey is absolutely non-negotiable. The mission here is to map out every single source of air movement that could possibly interfere with your effect. It’s the foundational work that makes or breaks the show.

During your survey, you need to identify and document:

- All HVAC Vents: Pinpoint every supply and return air vent in the performance space. Pay extra attention to floor-level and low-wall grilles, as they'll have the most direct impact.

- Air Current Patterns: Use a bit of theatrical haze or a small handheld fogger to actually see the air currents. This simple trick reveals the subtle drafts you'd never feel or see otherwise.

- Doorways and High-Traffic Areas: Doors opening and closing are like vacuums for fog, creating significant airflow that can pull the effect right off the stage.

Collaboration is your secret weapon. Don't go to the facility manager with a list of demands. Instead, approach them as a partner. Explain what you're trying to achieve and work together to find a way to temporarily adjust the HVAC system for the show.

Strategic Placement and Power Management

Once you've got a handle on the room's airflow, you can start positioning your low fog machines strategically. This means tucking them into spots shielded from direct drafts, giving the fog a fighting chance to settle and spread out naturally. Often, this means placing units upstage or behind scenery.

Just as important is power management. These machines, especially models with beefy heaters and cooling systems, are power-hungry. Always plug them into a dedicated circuit. The last thing you want is to trip a breaker mid-show, potentially taking out your lighting and sound along with the fog. In more complex setups, understanding modern power delivery is a plus; you can learn more about how systems like Power over Ethernet are managed in AV systems to appreciate why dedicated power is so crucial.

Finally, a quick but important note on air quality. When you're messing with a venue's HVAC, you need to think about what's already in the system. It's worth considering the potential health risks associated with dirty air ducts, because fog can stir up and circulate any dust or pollutants hiding in there. A clean system means your effect looks pure and the air stays safe for everyone.

How to Choose the Right Machine for Your Venue

Picking the perfect low fog machine isn't just about comparing spec sheets. It’s really about matching the technology to the unique demands of your space, the exact atmosphere you’re trying to create, and the skill level of your operators. Get this right, and you're investing in a flawless, professional result every single time.

It all starts with a practical framework. You need to weigh the size of your venue against what you plan to do with it. Are you trying to build a subtle, lingering mood for a theatrical play? Or do you need a massive, instant cloud for a high-impact product reveal?

Matching Technology to Application

Let's be honest, the needs of a local community theatre are worlds apart from a major concert tour. A small theatre can get fantastic results from a cost-effective, ice-based unit for specific scenes. It's a practical solution where the budget is tight and the machine will be run by in-house staff or volunteers.

On the other hand, a touring production or a large-scale corporate event absolutely needs the pin-point precision and cast-iron reliability of a DMX-controlled cryogenic system. In these high-stakes environments, the ability to trigger a perfectly consistent effect right from the lighting desk is non-negotiable. Downtime simply isn't an option, which makes the higher initial investment a must for guaranteed performance. This is precisely why powerful, tour-ready units like the Evolite EvoHeavyFog4000 are built for professional use—they offer the robust control that pros demand.

Evaluating Reliability and Support

In any professional setting, the reliability of your kit is everything. A machine that gives up the ghost mid-show is more than just an inconvenience; it can completely undermine an entire production. That's why it's so important to look beyond the price tag and consider the manufacturer's reputation for building durable, road-worthy equipment.

Just as crucial is the after-sales support you can get. When something inevitably goes wrong—and it will—having access to expert technical help can be a real show-saver. This is where partnering with a knowledgeable supplier becomes a strategic advantage, giving you the backup you need to keep your shows running without a hitch.

Choosing a low fog machine is not just a purchase; it's an investment in your production's quality. Reliability and expert support are just as critical as output volume or heat-up time, ensuring consistent, professional results night after night.

The Bigger Picture in the UK Market

While low fog machines are a specialised niche, they're part of a much broader fogging equipment landscape here in the UK. This market is actually dominated by thermal and ultra-low volume (ULV) machines used in completely different sectors, from agriculture to public health.

The demand for ULV systems, for example, has shot up for indoor disinfection, driven by a greater awareness of hygiene and indoor air quality. This trend shows a growing diversification of fogging technologies into all sorts of commercial settings, including the entertainment venues we work with. If you're interested in the wider market dynamics, you can discover more insights on the fogging machine market from Fortune Business Insights.

Navigating these choices—from the type of technology to the level of support you need—can get complicated. Getting some expert advice helps translate your creative vision into a technical specification, making sure the machine you choose is perfectly suited to your venue and delivers the unforgettable atmosphere your audience expects.

Safety, Maintenance, and Troubleshooting

A stunning low fog effect doesn't just happen by chance; it’s the result of a disciplined approach to both safety and maintenance. To get that consistent, reliable performance from professional low fog machines, the equipment needs to be looked after. This isn't just about protecting your investment—it's about ensuring the safety of performers, crew, and your audience.

Proactive care is your best defence against show-stopping failures and potential hazards. Before you even power on a specialised machine like this, it's vital to get your head around the risks by conducting a thorough risk assessment. This simple step ensures every part of the operation is viewed through a safety-first lens.

Essential Safety Protocols

If you take away one thing, let it be this: always use the manufacturer-approved fluid. It might be tempting to use a third-party or standard fog fluid, but this can wreck the internal heating element. More importantly, it can leave an oily, slippery residue on the stage, creating a serious slip hazard for anyone on it.

You also have to be mindful of the environment you're working in. The moisture from the fog can make smooth surfaces like Marley flooring or polished concrete incredibly slippery. It’s always good practice to have stage crew on standby with mops to manage any build-up, especially during longer performances.

Never compromise on fluid quality. The small saving you might make on unapproved fluid is simply not worth the risk of equipment damage or, worse, an injury.

Routine Maintenance Checklist

Regular maintenance is the secret to a long-lasting machine and consistent, beautiful fog. A straightforward checklist can help keep your units in peak condition, preventing the usual clogs and blockages that lead to weak or patchy effects.

Run through these steps after every few uses:

- Clean the Heat Exchanger: Get a specialised fog machine cleaning solution and run it through the system, just as the manufacturer recommends. This stops mineral and fluid residue from building up and clogging the heater block.

- Inspect Fluid Lines: Check all your hoses and intake filters for any blockages or kinks. Make sure the fluid line actually reaches the bottom of the tank so the pump doesn't run dry.

- Wipe Down the Exterior: Keep the machine's casing and vents clear of dust and debris. This ensures proper airflow and cooling, which is especially critical for refrigerated models.

- Check Power and DMX Cables: Give all your connections a regular once-over, looking for signs of wear and tear. A frayed power cable is a massive fire hazard.

Troubleshooting Common Problems

Even with the best maintenance schedule, things can go wrong during a live event. Here’s a quick guide to diagnosing and fixing the most common issues you'll face on the fly.

- Problem: The Fog is Rising: Nine times out of ten, the culprit is your venue’s HVAC system. Check that all the nearby air vents are closed or baffled. Even the slightest draft is enough to ruin the ground-hugging effect.

- Problem: Weak or Sputtering Output: This almost always points to a blockage. First, check you have enough fluid. If the tank is full, the machine probably needs a deep clean to clear a clog in the heater or the fluid line.

- Problem: No DMX Connection: Go back to basics. Is the DMX cable plugged in securely at both the machine and the console? Then, double-check that the DMX address on the machine is the same one you've patched on your lighting desk.

Answering Your Questions About Low Fog Machines

Even when you've got the technical side down, a few practical questions always pop up when planning an event with low fog machines. Let's tackle some of the most common queries we hear from AV pros, venue managers, and event planners.

Getting these details sorted upfront is the key to a flawless production and avoids any last-minute surprises on show day.

Will a Low Fog Machine Trigger Smoke Alarms?

This is the big one, and the honest answer is: it’s possible. While professionally made low fog fluid is designed to evaporate and is less likely to set off standard ionisation detectors, you can run into trouble with highly sensitive optical or beam detectors.

The idea is always to keep the fog effect well below any ceiling-mounted alarms. The problem is, unexpected air currents from the HVAC system can cause the fog to lift, which definitely increases the risk.

The best practice is always to run a test in the venue before the event. You'll need to coordinate with the building's facilities manager to find out what type of sensors are in place. If needed, they can help you safely and temporarily isolate the alarm zones covering the performance area.

What Is the Difference Between Low Fog and Standard Fog Fluid?

The fluid is every bit as important as the machine itself. Low fog fluid is specifically engineered to be denser and, most importantly, to dissipate very quickly once it warms up to room temperature.

This rapid evaporation is exactly what you want for a clean, ground-hugging effect. It stops the venue from slowly filling up with a general haze, which would completely kill the aesthetic you’re going for. If you try to use standard fluid in a low fog machine, you’ll just get a murky, ineffective cloud that won't stay low and hangs around for far too long.

How Much Do Professional Low Fog Machines Cost?

The investment needed for a proper low fog setup can vary massively, all depending on the technology and what you need it for. You really can’t just look at one price; the range is substantial.

- Entry-Level: An ice chiller attachment that you add to an existing fogger can be a good starting point, often setting you back a few hundred pounds.

- Professional Grade: For a robust, all-in-one cryogenic or refrigerated unit with full DMX control, built to survive the rigours of touring, you could be looking at anything from several thousand to well over ten thousand pounds.

That price gap reflects more than just the machine's output. It's about build quality, the precision of its control systems, and the rock-solid reliability you need for high-stakes professional shows.

At Epic Audio Ltd, we provide the expertise and equipment to help you create unforgettable atmospheres. Our team can help you select the perfect low fog solution for your venue's specific needs. Explore our range of professional AV solutions and get expert advice today.